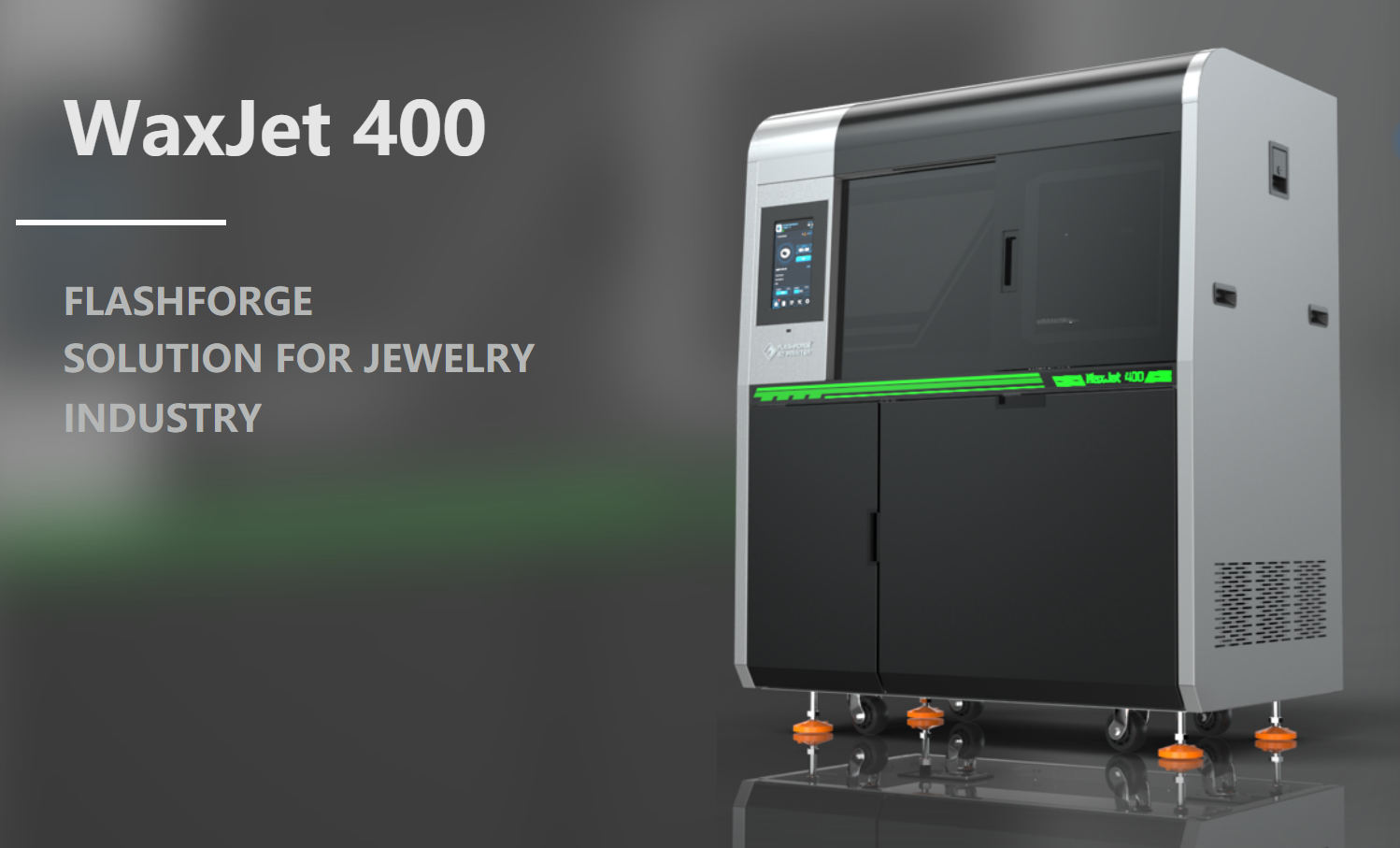

WaxJet 400 adopts mutiJet printing technology deliver smooth surface, high precision casting wax pattern with razor-sharp edges and extreme crisp details on each print. Suitable for designers and manufacturers of wax patterns for highly complex geometric shapes, jewelry, apparel, medical instruments and devices, mechanical parts, and collectibles.

Patent Number: 201830188448.1

Copyright Number: 2018-F-00024265